Shandong Aofeng Metal Material Co.,Ltd

Shandong Aofeng Metal Material Co.,Ltd

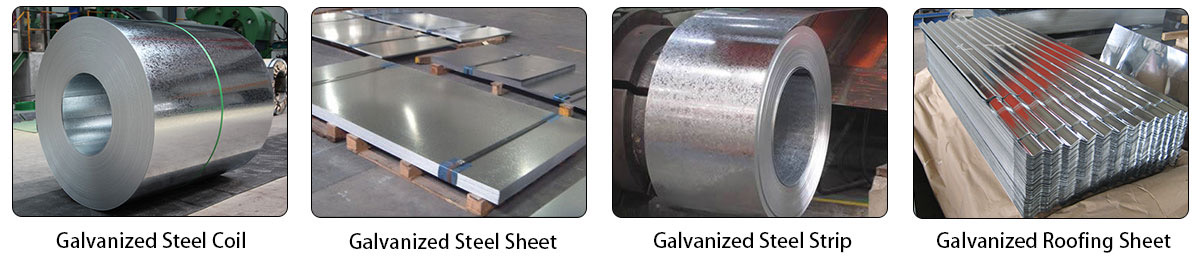

Product Specifications

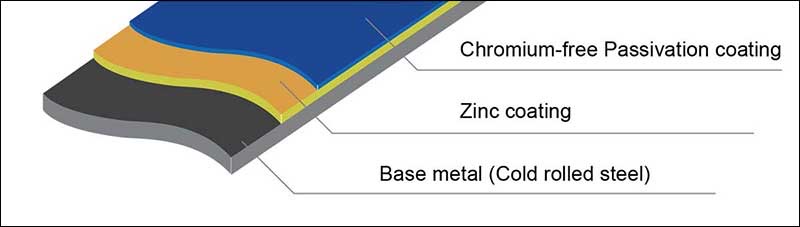

Diagram of Steel Surface Coating And Layers

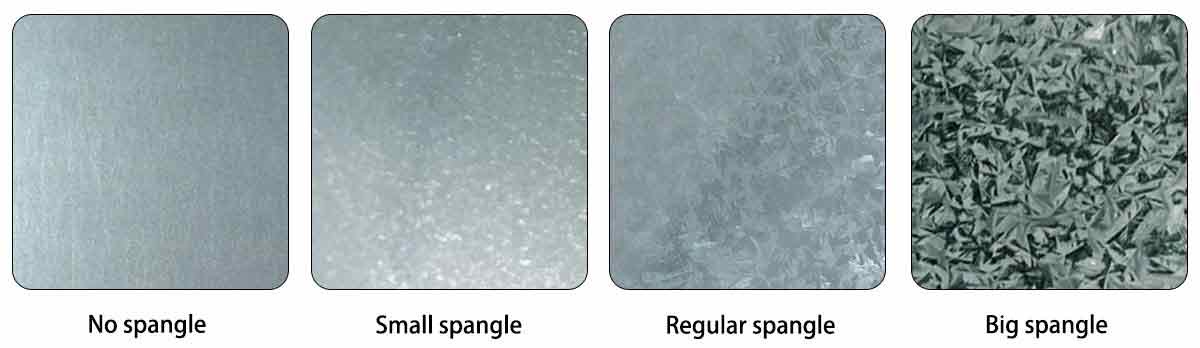

Surface Structure

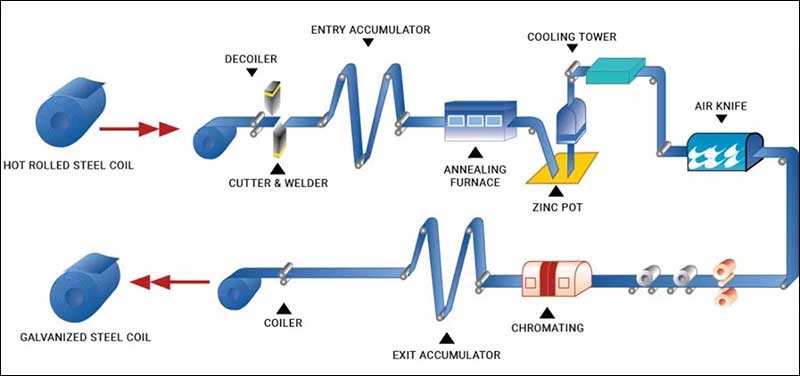

Production Process

01.Anticorrosive:13 years in heavy industrial areas,50 years in the ocean,104 years in the suburbs and 30 years in cities.

02.Cheap:The cost of hot-dip galvanizing is lower than that of other coatings.

03.Reliable:The zinc coating is metallurgically bonded to the steel and forms part of the steel surface,so the coating is more durable.

04.Strong toughness:The galvanized layer forms a special metallurgical structure that can withstand mechanical damage during transportation and use.

05.Comprehensive protection:Every part of the plated piece can be galvanized,and is fully protected even in depressions,sharp corners,and hidden places.

06.Save time and energy:Galvanizing process is faster than other coating methods.