Shandong Aofeng Metal Material Co.,Ltd

Shandong Aofeng Metal Material Co.,Ltd

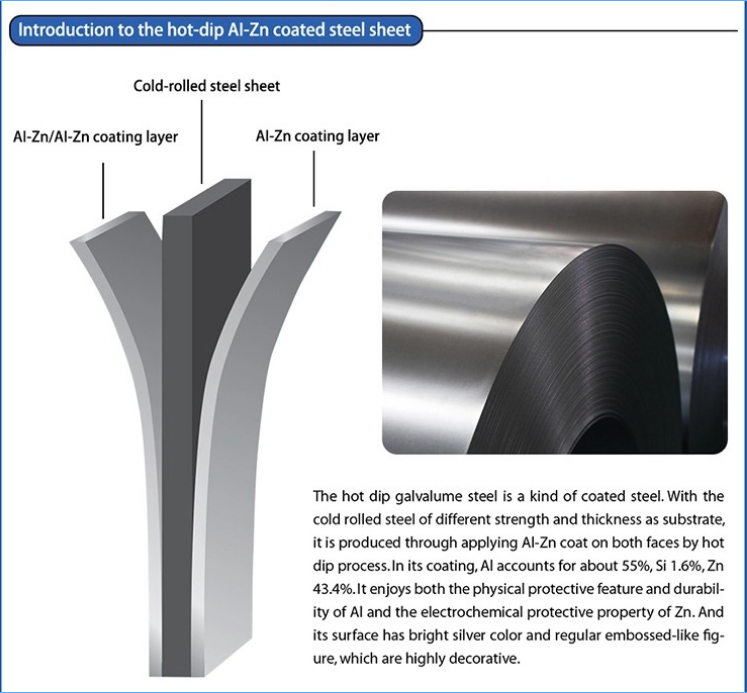

For galvanized coils, the thin steel plate is immersed in the molten zinc bath to make the surface of the zinc thin steel plate adhered. It is mainly produced by continuous galvanizing process, that is, continuous immersion of rolled steel sheets in a galvanizing tank with molten zinc to make galvanized steel sheets; alloyed galvanized steel sheets. This kind of steel plate is also manufactured by hot dipping method, but after exiting the tank, it is heated to about 500°C to form an alloy film of zinc and iron. This galvanized coil has good paint adhesion and weldability.

Contact:

Mr Jarven

Tel: +86-18563518078

Email: [email protected]

Wechat: +8618563518078 (Whatsapp)

Galvanizing process:picking-washing-adding zinc liquid-baking-galvanized-cooling-passivation-washing-flattening-finishing.

| Size | Thickness:0.12-4mm Tolerance:+/-0.01mm |

| ID | 508mm or 610mm |

| Basal plate | 1. Hot dip galvanizing2. hot dip aluminium-Zinc (55%aluminium,43zinc,2%si) |

| Zinc coating | 30- 275g/m2 |

| Standard and Materia | SGCC, SGCC, DX51D+Z, JIS G3321 ASTM A792M Q/BQB 420-1999 AS 1997 10147-90 EN 10147-90 |

| Production process | Cold rolled steel coil-uncoil-Pickling-Annealed-hot dipped galvanizing-cooling -surface treatment -rolling |

| Surface Treatment | Anti-finger prints (including gold silver blue and green) |

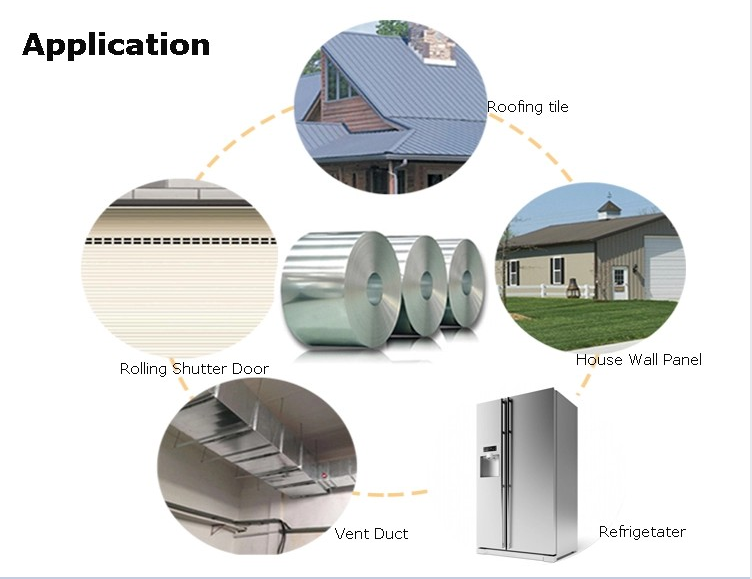

| Application | Gutters ,Auto parts ,Electrical Appliances,Purling,Vending Machine,Refrigerator, |

| Coil weight | 3-8MT/Coil or as your request |

Product Applucation

Galvanized sheet is mainly used: a large number of galvanized sheet plate used in automobile manufacturing, cooler, construction, ventilation and heating facilities and furniture manufacturing and other fields.

Galvanized become important steel anticorrosion method, not only bacause the zinc can be formed in the steel surface protective layer of dense, but also because of the zinc has the effect of cathodic protection, when the galvanized layer damage, it can still through the cathodic corrosion protection to prevent the iron base